Presentations

Getters and Getter Valves

The TGM uses getters to validate Warn and Alarm level readings.

The getters are selective chemical scrubbers used to establish a zero reading and used to validate a Warn level or Alarm level reading. Getter A is switched in line once every 10 minutes for the Zero Reference. It will remove any arsine or phosphine that should happen to be in the local air, improving the zero reference.The more significant role of the getters is the validation of the TGM's readings as it scans through its ports. A reading that exceeds the Warn level set point or the Alarm level set point causes the TGM software to:

- activate the corresponding Warn or Alarm relays

- activate the front panel light

- show details of the Warn or Alarm condition on the TGM display

- store the “incident” as a record in computer memory

- send the event to any printer or remote computer connected to the TGM

- send the event over the Local Area Network, if utilized

On the other hand, if one of the getters does cause the reading to drop by at least 50%, the computer will recheck the reading, making sure it goes back up to the Warn level or higher. Passing this validation causes the relay(s) to activate and the other “incident” events to occur:

- Warn level relays and messages, if the reading exceeds the Warn set point but not the Alarm set point

- Alarm level relays and messages if the Alarm set point is reached or exceeded

The specific getter(s) switched in for validation is determined by the gas type or types programmed on the sample port on which the leak is detected.

The specific getter(s) switched in for validation is determined by the gas type or types programmed on the sample port on which the leak is detected.Example: If phosphine is the only active gas on a port, then only Getter A will activate. If phosphine, diborane and silane are all active gases on a port, then the order of validation would be Getter A, Getter B and Getter C (valves SV25, SV26 and SV27). As soon as one of these getters scrubs out 50% or more of the gas, lowering the reading by 50% or more, that gas type is validated and the normal port scanning resumes.

If both Getter A and Getter B fail to remove the gas, but Getter C does remove it, the computer would determine that the gas type is silane. Silane would be identified by the readouts and reports, and the calibration data for silane (stored in computer memory) would be used to determine the concentration of silane in PPM units.

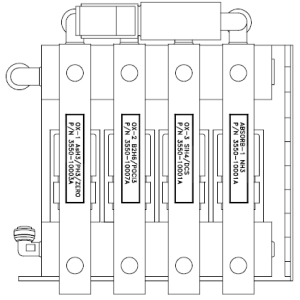

Most getters will remove more than one type of gas. In the standard configuration of the TGM, the getters and gases they remove are:

- Getter A: arsine/phosphine and zero

- Getter B: diborane/POCl3

- Getter C: silane/germane/WF6

- Getter D: ammonia/nitrous oxide